Date: June 28, 2024

Designer: Caleb Mueller

Objectives and Constraints

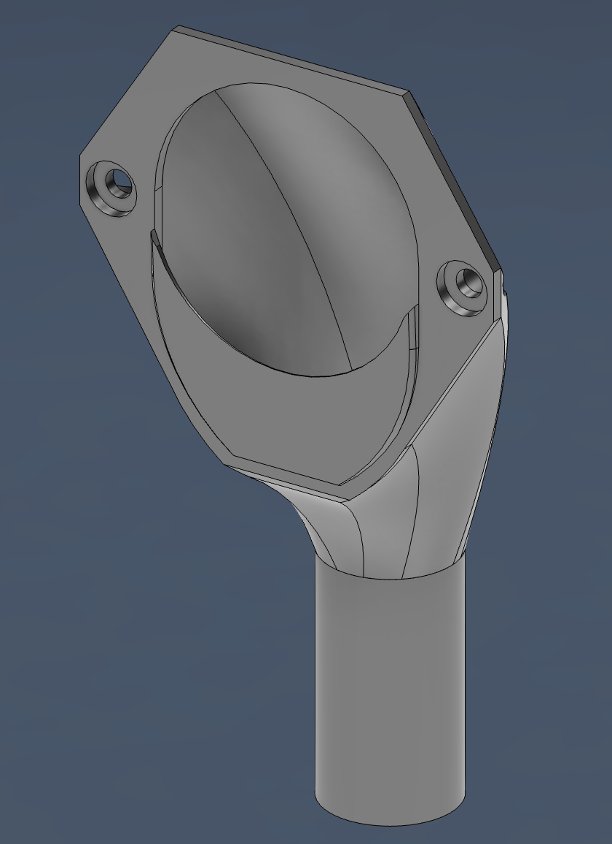

- Objective: Create a 3D printed sap collector that can accept a proprietary collection tube.

- Constraints: Must withstand being screwed into a tree and outdoor conditions.

Materials and Tools

- Software: Autodesk Fusion

- Materials: PLA and ABS filament

- Equipment: Voron Trident and Bambu X1C 3D printer

Phases of Development

I. Client Consultation

- Met with the client to determine the design criteria and properties of the sap collector. Measured the sap collection tube.

II. CAD Modelling and Prototyping

- The sap collector was modeled using Fusion. Prototypes were printed in PLA to test the fit of the collection tube.

III. Printing of Final Assembly

- A final sap collector was printed in ABS filament to withstand outdoor conditions.

Skills Developed

- Custom 3D printed screw holes

- Design to accept standard metal screws

- 3D prints for outdoor functional use

Support and Resources

Product Images

- Figure 1: Back view of 3D model