Date: March 11, 2024

Designer: Caleb Mueller

Objectives and Constraints

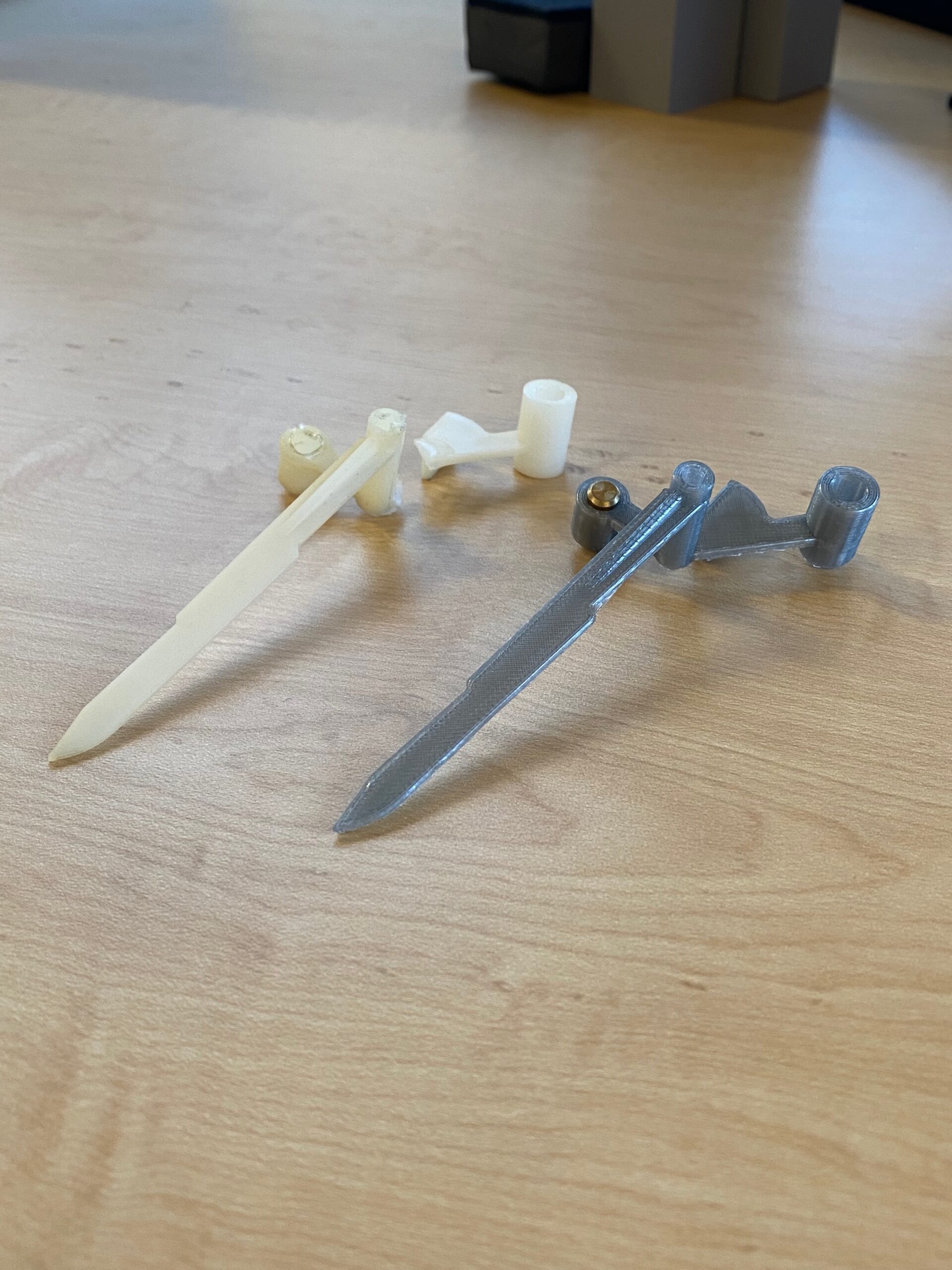

- Objective: Create a 3D printed polycarbonate actuator, modeled from a broken piece

- Constraints: Must fit a press-fit metal bearing from the original

Materials and Tools

- Software: Autodesk Fusion

- Materials: Polycarbonate filament

- Equipment: Bambu Lab X1C 3D printer and digital calipers

Phases of Development

I. Measurement

- The broken piece was temporarily glued back together and measured using calipers, then profile pictures were taken for reference.

II. CAD Modelling and Prototyping

- The actuator was modeled in Fusion using measurements and profile pictures as canvases for the more complex shapes.

III. Printing of Final Products

- The model was printed using PC filament and supports on a Bambu Lab X1-Carbon 3D printer. The original metal bearing was press fit into the replicated actuator.

Skills Developed

- Modeling of a complex shape using canvases

- 3D printing of a complex shape with support structures

- Tolerances for press-fit metal

Support and Resources

- Client Sydney Philpott provided photos of the finished product in use on the record player/turntable

Product Images

- Figure 1: 3D printed actuator in-use on the record player/turntable

Client Feedback

“The piece fit well into the record player, and it moves the record player arm like the old broken piece was meant to do!”

- Sydney Philpott