Date: July 10, 2024

Designer: Caleb Mueller

Objectives and Constraints

- Objective: Re-create/re-design a prototype of a tremor simulation device. Address the weaknesses of the original that caused it to break along the layer lines

- Constraints: Must screw into a proprietary wrist band and hold a motor and spinning weight.

Materials and Tools

- Software: Autodesk Fusion

- Materials: PLA filament, heat-set inserts

- Equipment: Bambu X1C 3D printer

Phases of Development

I. Client Consultation

- The broken model was plugged into power to demonstrate how the mechanism works. Consulted with client to determine the measurements and parameters needed for the 3D model and print.

II. CAD Modelling and Prototyping

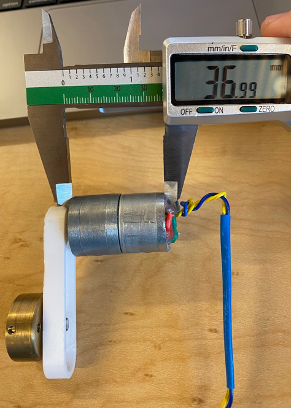

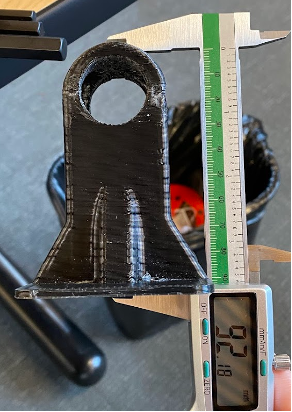

- Measurements were taken of the broken original prototype and the other components to be re-created in Fusion. A dynamic assembly was created so the movement of the device could be simulated before printing.

III. Printing of Final Assembly

- The final product was printed and assembled using heat-set inserts and screws.

Skills Developed

- Re-orientation of 3D printed parts for strength

- Joining an assembly using heat-set inserts/tolerances for heat-set inserts

- Dynamic assemblies in Fusion

Support and Resources

- Richard McAloney

- Centre for Technology Adoption for Aging in the North (CTAAN)

Product Images

- Figure 1: Taking measurements of the original broken prototype

Client Feedback

“The tremor simulation device is a tool that allows for the testing of a tremor reduction glove used by people living with essential tremor or Parkinson’s. It’s not a commercial product so when it broke it’s very difficult to replace. The team at Spark Lab was able to redesign the clamp and get the system operational in no time.”

– Richard McAloney